面临的挑战

One of the returnable glass bottling lines at the Coca-Cola Sabco site in Nairobi, Kenya was operating at an average performance of 68% OEE. They were hovering around this level and improvement efforts were delivering slow results. Their goal was for much greater performance and were finding those gains to be elusive. The glass line was old and over time, with equipment being changed and modified, had never gone through a process to set it up in a way that would maximise the accumulation of the line. The line had a good ‘V’ Curve so recovery was possible, but the speeds were not set to achieve the desired results.

The team approached LineView in hopes of finding performance gains without significant capital expenditure.

After completing an initial audit using the ‘5 Levels of Control’ methodology, LineView’s team of operational experts identified the following major challenges, mostly related to line balance, which were preventing the site from performance gains:

Issue #1: Conveyor speeds

The conveyors were not set at the optimum speeds and so in nominal state they were running mostly full.

On restart after a lack or build back, the speeds of the conveyors did not modulate and so were causing gaps and delayed restarts of the downstream equipment.

Issue #2: Machines stop/restart time

Restart times of the upstream machines were not optimised.

Issue #3: Dynamic accumulation

A large number of bottles were left at the downstream equipment when stopped. In addition, a large number of bottles were in transit between the equipment during nominal running conditions.

As a result, there were large unused spaces in build back when the equipment stopped.

解决方案

Based on the action plan, the team made several improvements to implement Line Balance Optimisation (LBO).

Optimised conveyor speeds:

- The conveyor speeds were optimised to reduce the amount of bottles in transit during nominal running conditions.

- The conveyors were enabled to modulate which delivered the bottles downstream.

Reduced restart times on machines:

- Reduced the amount of time taken to restart the upstream machines by implementing cascade control.

Maximised dynamic accumulation:

- The lack and build back sensors for all machines were repositioned to maximise the accumulation on the line.

What is Perfect Flow?

-

All equipment on the line runs in automatic with no manual intervention required.

-

In normal conditions the line speed is matched to the speed of the critical machine.

-

Minor stops on machines upstream or downstream do not affect the critical machine.

-

Extended stops affect the critical machine for a minimum period.

-

Critical machine starts almost instantaneously as the machines downstream after a build back situation.

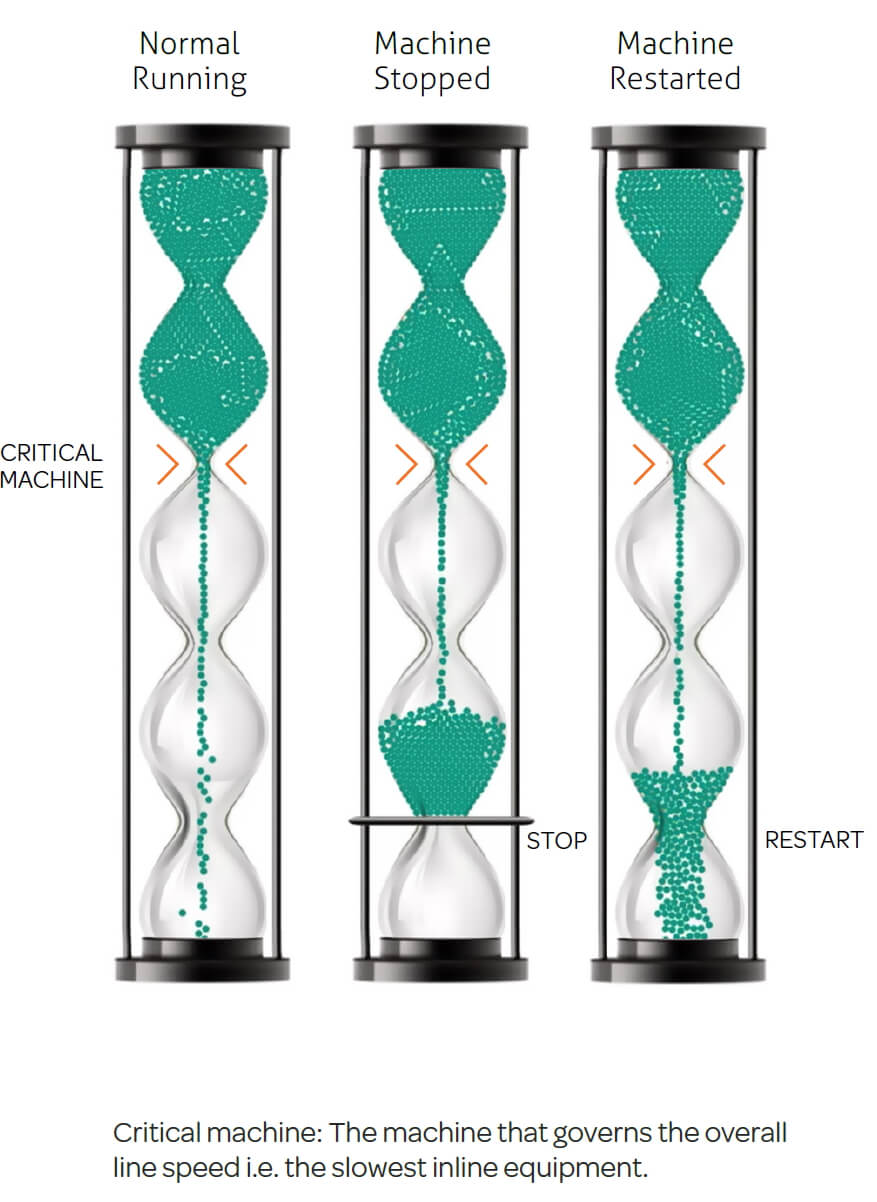

Normal Running:

- The critical machine runs at its rated speed and determines the line speed.

- Pre-critical machine, the line is full*.

- Post-critical machine the line is empty*.

*as much as possible

Machine Stopped:

- Equipment stops and product backs up.

- Other equipment stops due to product blocking outfeed.

- Critical machine eventually stops.

Machine Restarted:

- Affected machine restarts at maximum speed.

- All other equipment also restarts at maximum

speed. - Critical machine restarts (potentially instantly).

- Conveyors empty quickly due to speed differences

- Machines revert to nominal speed and line recovers

quickly.