Navigator.

One Platform.

Total Operational Insight.

Accelerate Productivity. Minimize Loss.

AI-Maximized Performance.

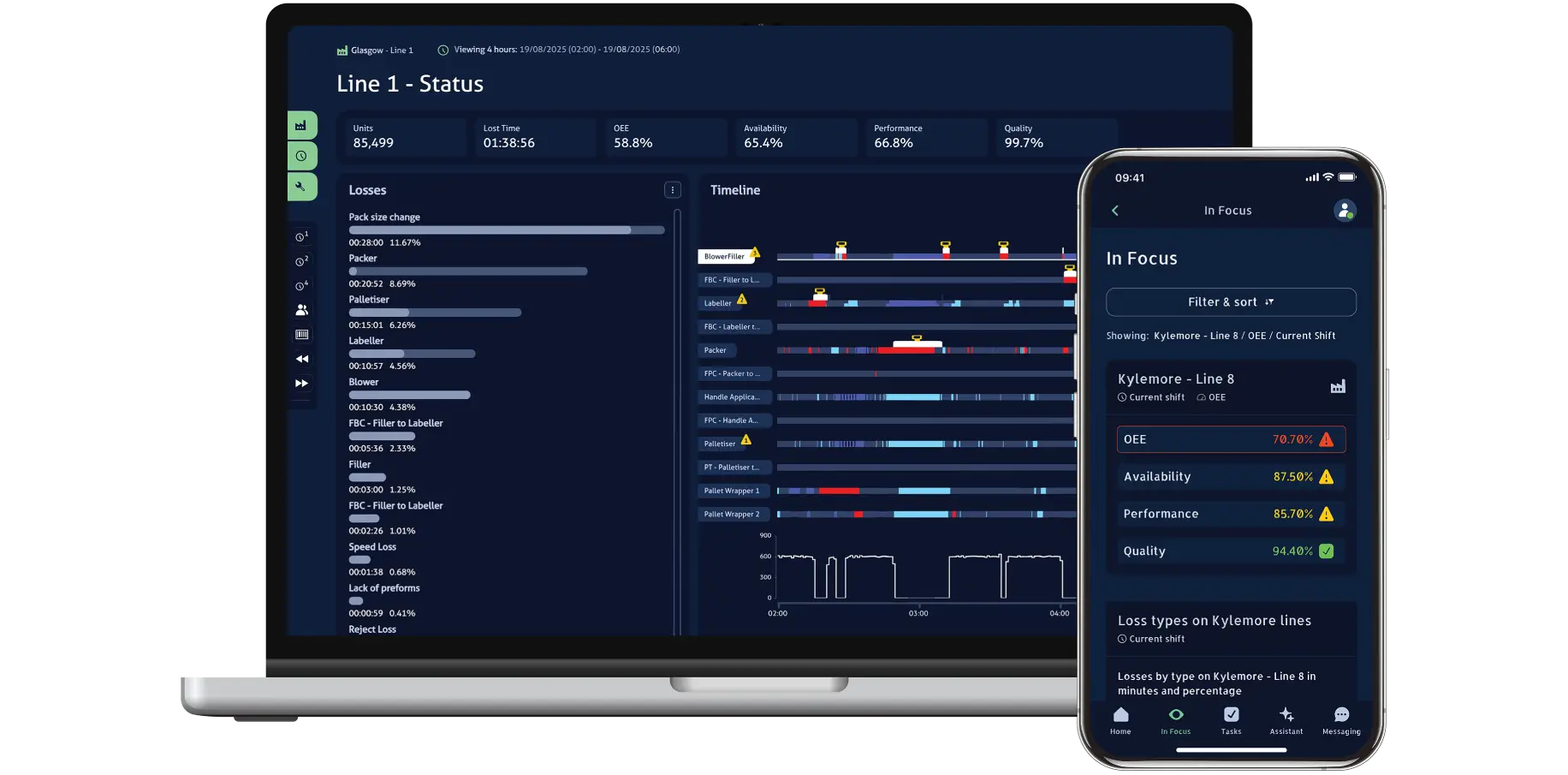

Lineview Navigator, our next-generation, cloud-based platform, delivers unified, real-time, and strategic views of operational performance and losses across production environments.

Navigator transforms the manufacturing process by empowering operators, managers, and central teams alike, to continuously improve overall equipment effectiveness (OEE) in manufacturing plants.

The best in the industry trust Lineview – from multi-national enterprises to single-site operations.

Navigator centralizes performance data across three powerful core modules

Global 24/7 API Access

Monitor

Real-time tracking & KPI monitoring direct from your production line

- Raw data within a 7-day window. Stored for 365 days, for historical comparison views

- On demand data visualization for the shopfloor, shift leaders and all who have access via a secure login procedure

- Minimal manual input required. Automated data integration for accuracy and speed. Data visualization prompts next-step action

Review

Tactical operational intelligence from your manufacturing sites

- Daily and weekly insights improve efficiency

- Collated raw data mirrors shift and factory-day schedules. Aggregate data presented with tactical focus. Raw data retained for up to three months

- User-friendly, visual dashboards for quick view access and investigation

Analyse

Strategic data for comprehensive analysis

- Data managed according to factory-day schedules. Data retained from day one

- Data collated and explored at production line, site, and group level reveals root causes of inefficiencies

- Long-term trend analysis and Performance benchmarking helps improve plant efficiency

Key features driving manufacturing transformation

Whether you’re on the shop floor or the boardroom, Navigator reveals the most relevant insights for your needs.

Faster decision-making at all levels

Improved OEE through targeted action

Reduced manual reporting burden

Greater team alignment and accountability

Accelerated continuous improvement cycles

Faster decision-making at all levels

Navigator empowers teams and inspires action by delivering reliable, accurate consolidated data, via user friendly dashboards that clearly signal improvement opportunities

Improved OEE through targeted action

Navigator supports teams at every level, to achieve next-level operational performance, by identifying losses, across production lines and improvement opportunities.

Reduced manual reporting burden

Navigator creates streamlined reports and long-term trend reports, helping your teams to identify losses, take action, and deliver results.

Greater team alignment and accountability

Navigator provides easy access to data across all levels of the business promoting a culture of data-driven decision-making.

Accelerated continuous improvement cycles

Data puts a spotlight on opportunities for change. Easy access to data highlighting operational performance and losses across production lines, creates greater focus on improvements.

Faster decision-making at all levels

Navigator empowers teams and inspires action by delivering reliable, accurate consolidated data, via user friendly dashboards that clearly signal improvement opportunities

Improved OEE through targeted action

Navigator supports teams at every level, to achieve next-level operational performance, by identifying losses, across production lines and improvement opportunities.

Reduced manual reporting burden

Navigator creates streamlined reports and long-term trend reports, helping your teams to identify losses, take action, and deliver results.

Greater team alignment and accountability

Navigator provides easy access to data across all levels of the business promoting a culture of data-driven decision-making.

Accelerated continuous improvement cycles

Data puts a spotlight on opportunities for change. Easy access to data highlighting operational performance and losses across production lines, creates greater focus on improvements.

Reducing cost and protecting revenue

While raw material, labor, and indirect costs surge, manufacturers are looking for ways to control manufacturing process costs and improve overall equipment effectiveness in plants.

Navigator performance data helps businesses to answer two fundamental questions:

- How much did we produce?

- How much should we have produced?

With detailed causal loss tracking, site and line analysis, Navigator supports customers to reduce operating expenses, enhance manufacturing efficiency, thereby increasing revenue.

Enabling the Future of Manufacturing

By combining real-time data, AI-driven insights, and proven operational excellence methodologies to unlock the full potential of your production lines – Navigator turns manufacturing performance into a strategic advantage

Driving Action from Insight

- Navigator bridges gaps between analytics and execution

- Data points are transformed into contextualized, prioritized opportunities for improvement, and delivered directly to decision makers

- Built-in workflows and real-time alerts, turns performance metrics into immediate, measurable impact on the shop floor

Expertise Embedded in Every Click

- Decades of operational excellence, distilled into a digital experience and world class intelligence

- Our software embeds proven improvement methodologies—like Lean, Six Sigma, and TPM—directly into daily workflows

- We equip teams with tools, knowledge, sector experience and structure to sustain progress

Smarter Manufacturing with AI

- Our platform learns from performance combining power of AI with Navigator

- We help manufacturers predict downtime, optimize performance, and detect patterns invisible to the human eye by applying advanced machine learning to real-time production data

- The result? Less guesswork, more foresight—and a smarter, more agile operation

IFA methodology

Driving operational excellence together

Lineview’s IFA (Information × Focus × Actions) methodology guides you to focus on the inputs, which enables the path to operational excellence and guaranteed results.

We go beyond installation by partnering closely with customers through collaborative goal-setting, shared accountability, and on-site coaching to ensure lasting success.

Ready to see Navigator in action?

Navigator bridges real-time operations and long-term strategy. Discover how you can drive manufacturing excellence with a single, powerful platform.

Customer Stories

Dive into how LineView empowers manufacturers to transform production. We believe success is a two-way street (win-win), so explore how our customers win big, and how their success fuels our drive to keep innovating.

CASE STUDY

Coca-Cola Enterprises selects Lineview as their system of choice.

Lineview has been implemented at CCEP over the past 25 years and has been the specified application for all new territories acquired during that time to increase efficiency and reduce costs.

CASE STUDY

AB InBev China achieves Goals through Data, focus and action.

The world’s largest brewer, AB InBev, recommended Lineview to their Chinese bottling plant based in Wuhan to remedy the company’s struggles with efficiencies.

CASE STUDY

Chivas Brothers Pernod Ricard increases mechanical efficiency by 17% in six months.

Line 33’s Mechanical Efficiency increased from 60% to 70% after six months of data-driven interventions and focused improvements.