Are you struggling with bottleneck machine speed,

under-utilized conveyors, and inefficient stops and starts?

Ineffective production line balancing formula and control is often the most overlooked OEE improvement opportunity, despite being easy to achieve.

Proven Line Balancing steps are simple to apply and deliver quick-wins with sustainable improvements, most-often requiring no capital expenditure. Building from an initial audit using the ‘5 Levels of Control’ line balancing methods, our operational experts will work with your team to achieve Perfect Flow.

Does your production line meet the following line balancing steps?

If so, you can take advantage of our Line Balancing formula to achieve Perfect Flow.

- You’re running a “Traditional V-Curve” production line

- Accumulation conveyors are often full during stable operation

- You experience start-up delays between machines

- Your stop – start process requires human interaction with machines

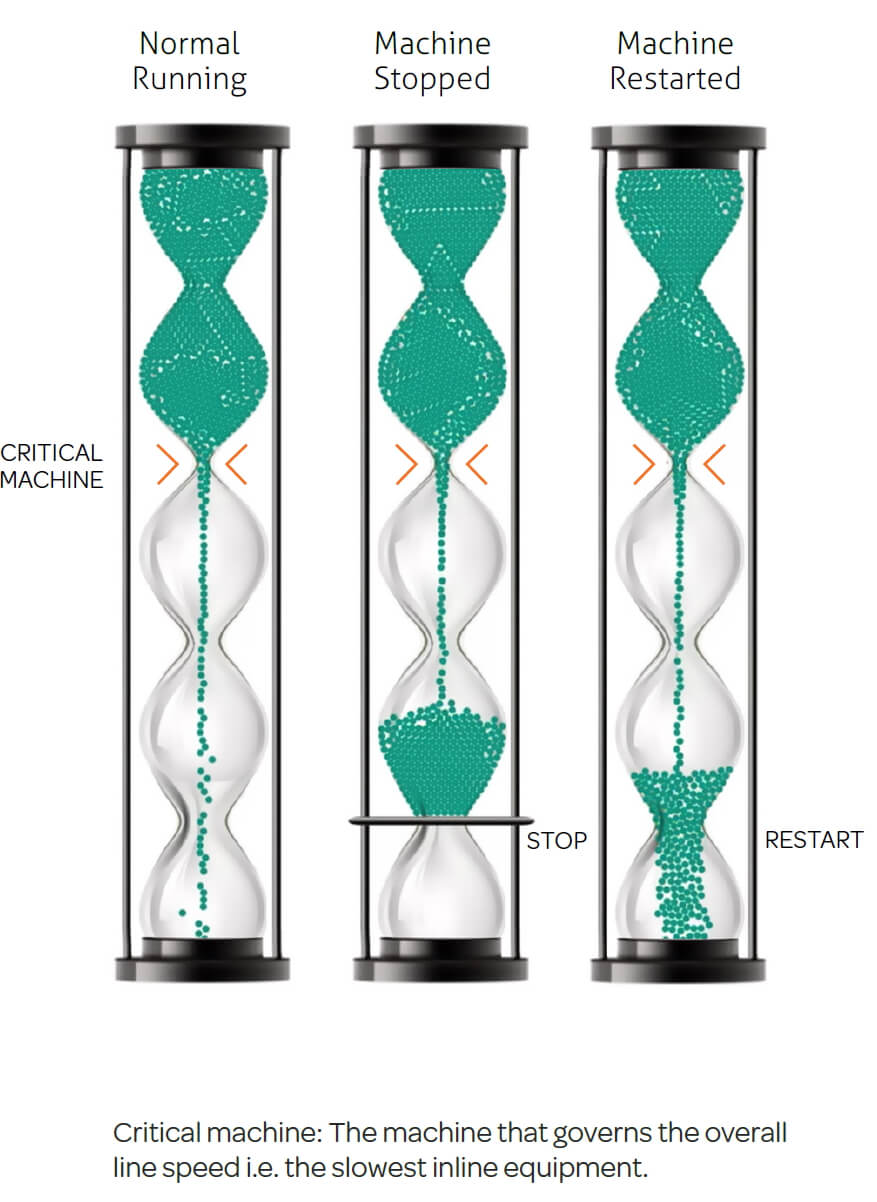

Perfect Line Balancing Example

Perfect Line Balancing Example

Normal Running:

- The critical machine runs at its rated speed and determines the line speed

- Pre-critical machine, the line is full*

- Post-critical machine the line is empty*

*as much as possible

Machine Stopped:

- Equipment stops and product backs up

- Other equipment stops due to product blocking outfeed

- Critical machine eventually stops

Machine Restarted:

- Affected machine restarts at maximum speed

- All other equipment also restarts at maximum speed

- Critical machine restarts (potentially instantly)

- Conveyors empty quickly due to speed differences

- Machines revert to nominal speed and line recovers quickly

“Our proven line balancing template identifies the gap between your current state and perfect conditions.

The actions are then defined and the potential savings calculated”

Proven line balancing methods developed by our operational excellence experts at OptimumFX, Line Balancing Formula enables perfect flow for accumulation conveyors:

- All equipment on the line is balanced and controlled automatically, without manual intervention.

- Speed of the line matches critical machine speed under normal conditions.

- Minor stops on upstream or downstream machines do not affect the critical machine.

- The critical machine is minimally affected by extended stops.

- The critical machine is restarted almost instantaneously after a build back situation.

Start with an operational audit to learn how our 5 Levels of Control can optimise your line.