Fast-Track Company-Wide KPI for Manufacturing Performance

Cost-effective manufacturing that meets corporate sustainability and performance goals.

Standardize performance and achieve measurable results across sites in as little as six months with Lineview Smart Start.

Inconsistent Operations Slowing Progress Against Corporate Targets?

Performance Variability Across Sites

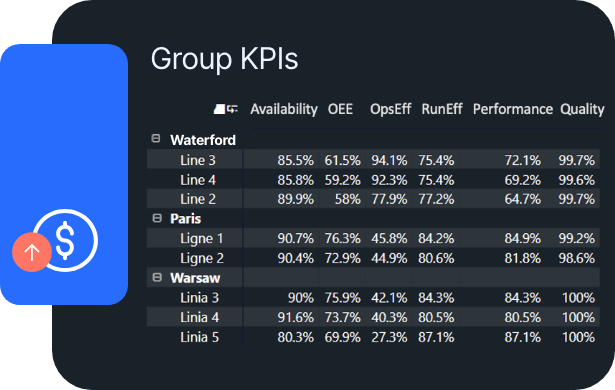

Without enterprise-wide standardization and smart manufacturing KPI tracking, variability in site-level performance can result in problem sites operating at as low as 50% capacity.

Struggling to Meet Sustainability Targets Without Disruption

Balancing energy efficiency and CO2 reduction with production targets is a challenge—but delaying action risks falling short of corporate mandates.

Rising Costs Eroding Margins Across Facilities

Labor and operational costs continue to climb, putting pressure on site-level profitability and making KPI for manufacturing performance harder to achieve.

Lack of Real-Time Visibility for Strategic Decision-Making

Fragmented data systems and limited insights make it harder for site-level leaders to act decisively, slowing progress toward global benchmarks.

Lead the Charge. We’ll Power Your Results.

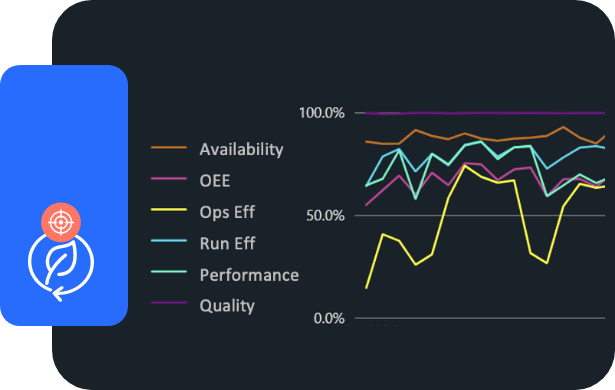

Lineview Smart Start combines our Navigator Core insights, manufacturing KPI dashboard, expert-led guidance, and the power of the Global Manufacturing Index to help manufacturing leaders and corporate directors navigate the complex decisions limiting capacity and cost savings.

Drive Measurable Sustainability Gains

Identify energy efficiency and CO2 reduction opportunities, ensuring you hit sustainability targets without disrupting operations.

Standardize Performance Across All Sites

Leverage manufacturing KPI dashboard, GMI benchmarks and Navigator Core insights to align site-level operations with corporate goals and drive consistent performance.

Optimize Labor Utilization and Cost Efficiency

Our hands-on team will work alongside your site-level leaders to identify each line’s waste fingerprint, track KPI for manufacturing performance, reduce loss, and maximize workforce productivity.

Speed Up Decision-Making

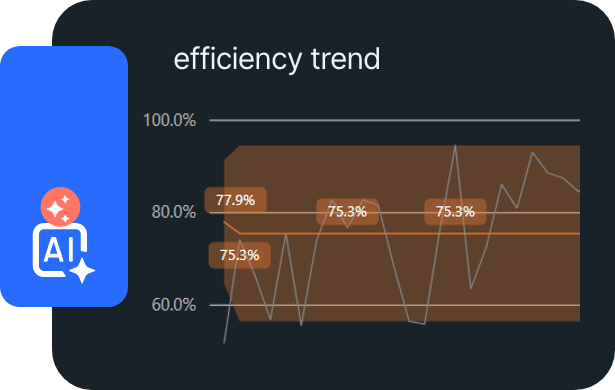

Navigator Core provides actionable, AI-driven insights that enable faster, more strategic decisions across facilities.

Why Corporate Manufacturing Leaders Choose Lineview Smart Start

Take the Next Step Toward More Cost-effective Manufacturing

Achieving global sustainability and performance goals – without adding cost or losing capacity – starts with actionable insights and a data-driven plan. With Lineview Smart Start, you’ll align operations, track essential KPI for manufacturing performance and gain clarity across your sites—all in as little as six months.

Ready to fast-track your site/company’s manufacturing performance?